The Project

The Motivation

Most multicopters feature fairly simple configurations made of semifinished products and conventional or fiber-reinforced plastics (FRP). The latter have deficiencies in structural efficiency and come with the major environmental problems associated with plastics. The production of FRP involves energy-intensive processes and includes fossil raw materials (e.g. polymers made from propene) as well as critical raw materials (e.g. catalysts made from bismuth or platinum). At the end of the service life of FRP components, the poor recyclability is problematic, as no complete material recycling processes exist. Compared with metallic or wood-based materials, the use of FRP is associated with higher costs, since the complex production of fibers, matrix and components generally involves a high material and labor input.

The Idea

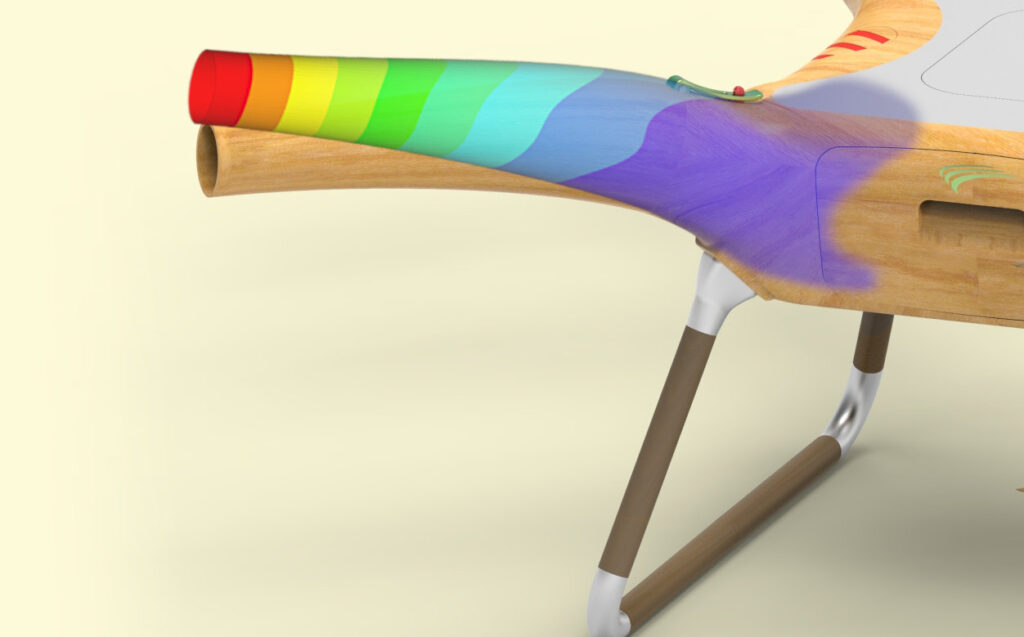

In view of the rapid global economic development of recent decades and the associated problems of environmental degradation, resource exploitation and climate change, it is becoming increasingly important to create more sustainable products and economic models. In the HerMes project, a multicopter system with a significantly improved sustainability is being developed. Suitable materials and manufacturing processes based on renewable raw materials are being used for this purpose. In particular, wood and natural fiber-reinforced bioplastics offer excellent structural-mechanical properties as well as good recyclability and cost efficiency.

Efficiency

Conventional FRP are virtually “overqualified” for all those applications in which their high specific strengths and stiffnesses clearly exceed the moderate load requirements. An example of this are smaller unmanned aerial systems, such as in the HerMes project. Wood and natural fiber materials have excellent specific strengths and stiffnesses comparable to those of aluminum and steel. This makes them particularly interesting for such applications with moderate load requirements, where they lead to lighter, more efficient structures compared to conventional FRP and enable reduced energy and resource consumption as well as potential for increasing payload capacity and/or flight time.

Qualification

From the very beginning, the multicopter is being developed with a view to later technical qualification in order to enable demanding and safety-critical applications, e.g. flight operations in SORA SAIL III/IV. Such a technical development is characterized by great complexity. Due to the strong dependency of the individual development areas (e.g. structural design, avionics, propulsion) on each other, a high degree of interdisciplinarity results, which requires a well-structured project organization as well as profound competencies of the partners involved. The HerMes project brings together a powerful and well-networked consortium that possesses these qualities and works on the essential tasks in a goal-oriented manner. In addition to the aeronautical development of the aircraft, these tasks include the development of advanced structural materials, new adhesive systems and surface protection agents based on renewable raw materials.